Indoor Air Quality Solutions.

In 2025, clean indoor air is no longer a luxury; it has become a building standard. Across Vancouver, BC, and throughout Canada, developers, engineers, and owners expect high-performance commercial HVAC systems and indoor air quality solutions (IAQ) as part of every new build.

At True Mechanical, we’ve made indoor air quality solutions part of the blueprint, not an afterthought. From HEPA filtration to UV-C air purification and whole-building purification systems, we’re integrating advanced air technologies into commercial HVAC and plumbing projects across British Columbia and beyond.

Why Indoor Air Quality Matters in Vancouver and Across Canada.

Most Canadians spend nearly 90 per cent of their time indoors, and in dense urban regions like Vancouver, indoor air can often be more polluted than outdoor air. Construction materials, wildfire smoke, and poor ventilation all contribute to degraded air quality in both residential and commercial buildings.

Modern indoor air quality solutions do far more than control temperature; they safeguard occupant health, productivity, and comfort. The benefits are especially critical in high-rise residential developments, office towers, and institutional facilities across BC, where air is shared across multiple zones. True Mechanical’s IAQ design approach helps solve key problems such as:

- Smoke and particulate control during BC’s wildfire season

- Pathogen and bacteria mitigation through UV-C purification

- VOC and odour reduction in tightly sealed high-rise towers

- Improved ventilation and humidity balance via energy recovery systems

- Long-term mechanical system performance with cleaner coils and reduced fouling

Core Technologies Driving Better Indoor Air Quality Solutions in BC and Beyond.

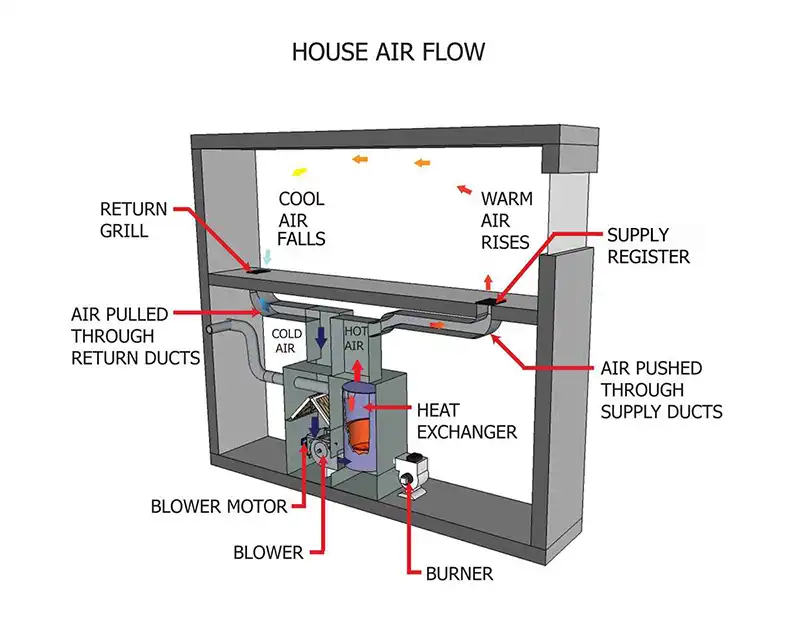

The best indoor air quality solutions layer multiple technologies to provide comprehensive protection. Here’s how the main components work together in commercial HVAC systems across Vancouver and Canada:

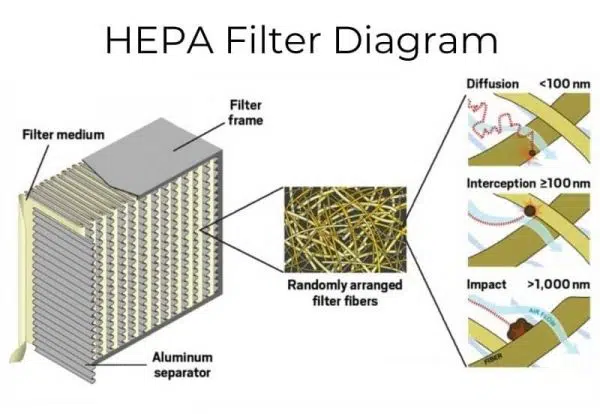

HEPA (High-Efficiency Particulate Air) Filtration.

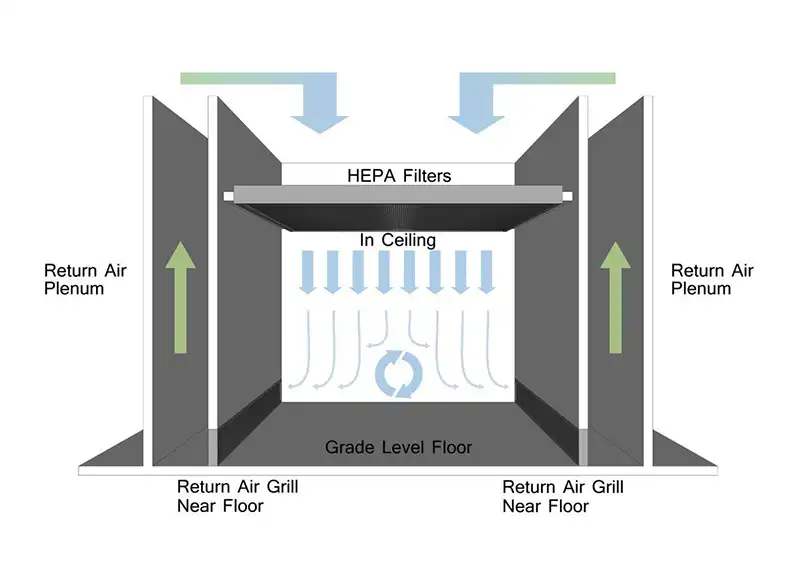

HEPA filters remove 99.97 per cent of particles as small as 0.3 microns, capturing allergens, smoke, and fine dust. In the Lower Mainland, where wildfire smoke and urban pollution are increasingly prevalent, HEPA filtration has become a design essential for both commercial HVAC projects in Vancouver and multi-unit residential towers. Key considerations include pressure drop (requiring higher-capacity fans), airtight housings to prevent bypass, and staged pre-filters to extend filter life. Many mechanical contractors in BC now design these systems from the ground up to ensure compatibility with HEPA specifications.

UV-C Air Purification.

UV-C disinfection systems use ultraviolet light to neutralise airborne microbes. Installed at cooling coils or within ducts, they reduce biological growth, prevent mould, and enhance system hygiene. Across BC commercial HVAC projects, UV-C is particularly valued for its ability to keep large-scale systems operating at peak efficiency while reducing pathogen spread in shared environments such as universities, hospitals, and high-rise offices.

Whole-Building Purification Systems.

Whole-building indoor air quality solutions integrate HEPA filtration, UV-C, and activated carbon stages into a single mechanical sequence. These duct-mounted systems treat air as it circulates through a building’s central HVAC infrastructure, ensuring uniform air quality across all zones. New construction in Vancouver and the Okanagan increasingly includes these systems at the design stage to future-proof buildings and meet WELL or LEED certification targets.

Ventilation, ERVs, HRVs, and Monitoring.

True Mechanical designs ventilation systems that meet or exceed ASHRAE and CSA standards for air change and recovery. Energy Recovery Ventilators (ERVs) and Heat Recovery Ventilators (HRVs) bring in fresh air while reducing energy loss, a vital feature for Vancouver’s mild, moisture-heavy climate. Sensors for CO₂, VOCs, PM 2.5, and humidity feed into automated building management systems, allowing dynamic adjustments to maintain optimal IAQ in real time.

Economics: Cost vs Benefit in Commercial HVAC Vancouver Projects.

Upgrading to advanced IAQ systems typically adds 5–15 per cent to upfront mechanical costs, depending on system scale. However, in exchange, owners experience improved tenant retention, lower maintenance costs, and reduced energy waste resulting from cleaner equipment operation.

In high-rise construction projects across BC and Alberta, owners are seeing tangible returns, lower absenteeism, higher occupant satisfaction, and enhanced property value driven by healthier building branding. Over time, IAQ improvements can lead to faster leasing cycles and a stronger market positioning.

Indoor Air Quality Solutions Installation Challenges and Design Considerations.

While the benefits are significant, advanced purification systems demand early coordination between design teams, engineers, and mechanical contractors. Key factors include:

- Sizing fans and ducts for HEPA pressure losses

- Allocating service space for filters and UV lamps

- Ensuring UV-C exposure zones are safe and effective

- Integrating IAQ controls with existing automation systems

- Managing ceiling space in high-rise retrofits

By involving True Mechanical’s design and pre-construction teams early, builders avoid the retrofit pitfalls common in tight Vancouver mechanical rooms and achieve seamless integration with architectural design.

Future Trends in Indoor Air Quality for BC and Canada.

Technological advancements and regulatory developments are shaping the future of indoor air quality in Canada’s construction sector. Trends include:

- AI-driven HVAC controls that predict occupancy and outdoor pollution levels

- WELL and LEED alignment, making IAQ metrics part of building certification

- Low-energy purification systems that balance efficiency with health outcomes

- Intelligent monitoring dashboards providing real-time IAQ visibility for owners and tenants

- Modular purification systems that can be upgraded as standards evolve

The future of clean air – True Mechanical.

Across Vancouver and Western Canada, True Mechanical continues to lead mechanical innovation, collaborating with clients and engineers to integrate these next-generation systems from the earliest design phase.

If you have a project you’d like to discuss, contact our team and lets make something happen.

Frequently Asked Questions (FAQ)

What are the most common air purification systems used in commercial HVAC across North America?

HEPA filtration, UV-C disinfection, activated carbon adsorption, and integrated purification modules are the most common. These systems are often combined to improve air quality in high-density environments like high-rises and institutional buildings.

What is HEPA filtration?

HEPA stands for High-Efficiency Particulate Air. These filters remove at least 99.97% of particles as small as 0.3 microns, including smoke, pollen, bacteria, and dust.

What standards and codes govern air purification systems in Canada?

Indoor air quality systems are regulated under ASHRAE, CSA, and local BC building codes. Additional guidance comes from WELL and LEED certification frameworks, which are now common in new construction projects across Vancouver and Canada.

How often should air filters and purification components be serviced in commercial HVAC systems?

Most commercial buildings in BC replace pre-filters every 3–6 months and HEPA filters every 12–18 months, depending on load and usage. UV-C lamps typically require annual replacement to maintain disinfection strength.

Are UV-C purification systems safe for occupants?

Yes—when installed by certified mechanical contractors and properly shielded, UV-C systems operate safely within ducts or air-handling units. True Mechanical follows CSA and ASHRAE guidelines to ensure compliance and zero ozone generation.

Can HEPA or UV-C systems be added to existing HVAC installations in Vancouver?

In many cases, yes, but retrofits may require upgraded fan capacity or duct reconfiguration to accommodate higher pressure drops. True Mechanical’s design-assist teams assess feasibility early to avoid costly rework later.

What are the economic benefits of upgrading to advanced Indoor Air Quality Solutions.?

Although upfront costs are 5–15% higher, clients in BC typically see improved tenant retention, fewer maintenance calls, cleaner coils, and lower absenteeism—delivering strong long-term ROI and energy savings.

How does indoor air quality affect employee productivity and health?

Cleaner air reduces headaches, fatigue, and respiratory symptoms. Studies in Canada and the US show productivity improvements of 8–11% when IAQ meets modern ventilation and filtration standards.

What role do mechanical contractors play in designing IAQ systems?

Mechanical contractors like True Mechanical coordinate design, sizing, installation, and commissioning of IAQ systems. Their role ensures that filtration, ventilation, and control systems function together seamlessly and meet local BC codes.

Are there government incentives for IAQ upgrades in BC or Canada?

Yes—CleanBC and Natural Resources Canada occasionally offer rebates or grants for energy-efficient ventilation and IAQ improvements in commercial buildings. True Mechanical can advise clients on available programs.

What’s the difference between MERV and HEPA filters?

MERV filters range from 1–16 and measure efficiency at capturing larger particles. HEPA filters go further, capturing 99.97% of 0.3-micron particles. In high-rise and institutional projects, both are often used in stages for optimal performance.

What’s the best IAQ solution for new high-rise construction in Vancouver?

The best results come from layered systems: ERV or HRV ventilation, MERV-to-HEPA filtration, UV-C disinfection, and real-time monitoring. True Mechanical integrates these early in the design process to future-proof buildings.

Can IAQ systems help mitigate wildfire smoke in BC?

Yes. HEPA filtration, activated carbon filters, and proper pressurization help keep particulate matter and odors out of occupied zones during wildfire events—now an annual concern across Western Canada.

What is an Energy Recovery Ventilator (ERV)?

An ERV transfers both heat and humidity between outgoing and incoming air streams. In Vancouver’s mild and humid climate, ERVs help maintain comfort while reducing the energy required to condition fresh air.

What is a Heat Recovery Ventilator (HRV)?

An HRV transfers heat only, not moisture, between exhaust and fresh air. These systems are ideal for drier Canadian regions or tightly sealed buildings where humidity control is managed separately.

What emerging IAQ technologies should builders in BC be aware of?

AI-driven HVAC controls, smart sensors, modular purification units, and low-energy plasma filtration are advancing quickly. These technologies are reshaping how buildings self-monitor and adjust air purity levels.

How does True Mechanical ensure its IAQ systems meet sustainability goals?

True designs prioritize energy recovery, efficient fan selection, and lifecycle cost analysis. Our IAQ systems align with CleanBC, WELL, and LEED objectives to balance occupant health with environmental performance.

Why is early mechanical design coordination important for IAQ systems?

Integrating purification systems early allows for correct fan sizing, duct routing, electrical capacity, and maintenance access. True Mechanical’s design-assist process ensures systems are planned, not patched in later.

Do these systems require additional energy?

Yes, advanced filtration and UV-C systems add modest electrical load due to fans and lamps. However, improved efficiency from clean coils, balanced airflow, and reduced maintenance often offsets those costs.

How can I learn more about indoor air quality standards in Canada?

Visit ASHRAE, CSA, or Health Canada’s Indoor Air Quality Guidelines for technical references, or contact True Mechanical’s Vancouver office for project-specific consultation.