HVACR and Plumbing Innovations Racing to Meet AI’s Demands.

The explosive growth of artificial intelligence, high-performance computing, and quantum computing is reshaping how the world thinks about data centre infrastructure. As computational intensity surges, so does the heat, and nowhere is this more apparent than in the essential, rapidly developing fields of HVACR and Commercial Plumbing for data centres, especially those supporting immense AI workloads.

This article explores how engineers, manufacturers, and operators are reimagining, testing, and deploying breakthrough cooling strategies at record speed to keep pace with the relentless demands of the digital age.

Why AI is changing the cooling equation.

Traditional data centres often relied on air-cooled systems and steady, predictable workload patterns. AI facilities, however, demand something different.

Modern data centres are operating at far greater computing densities thanks to advanced GPUs, FPGAs, and specialized processors that deliver immense power and generate substantial heat in increasingly compact spaces. Unlike traditional systems that experience sporadic load spikes, today’s infrastructures run at peak intensity around the clock, placing continuous stress on cooling and thermal management systems.

The emergence of quantum computing and related technologies is pushing these boundaries even further, producing levels of heat output once unimaginable. As a result, mechanical engineers face a new set of problems and opportunities that are rapidly accelerating the industry’s innovation cycle.

Precision environmental controls.

The move toward “precision HVACR” means tighter control over temperature and humidity, typically via hot-aisle/cold-aisle containment, zone-based systems, and rapid-response sensors. These methods help isolate heat and maintain stable conditions, which are essential to the reliability and efficiency of advanced computer workloads.

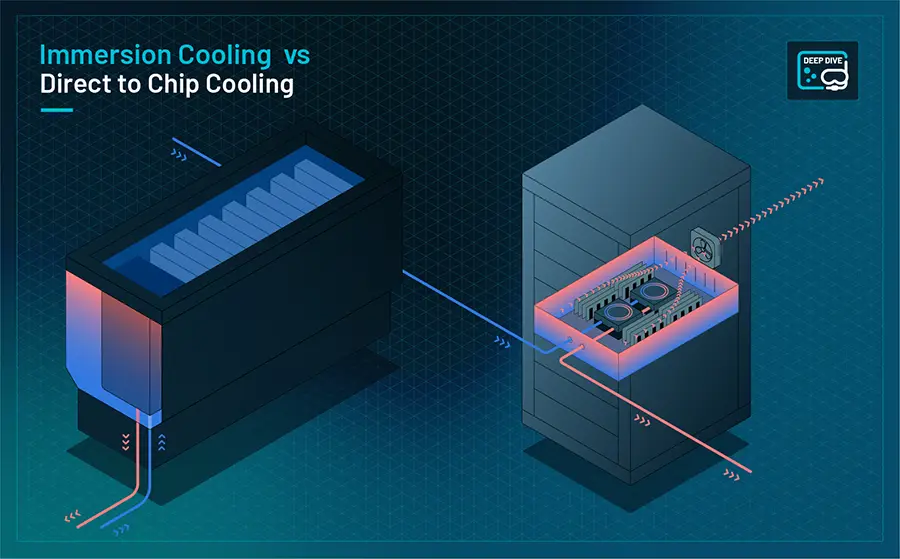

Liquid cooling and immersion technology.

A revolution is underway in direct liquid-cooling and full-immersion systems. Unlike air cooling, these solutions deploy cold plates and dielectric fluids to extract heat right at the processor or server surface.

Liquid cooling circuits circulate chilled coolant directly to high-heat components, transferring thermal energy to central chillers or heat exchangers for rejection. Complete immersion pods take this further by submerging entire server racks in non-conductive coolants, dramatically increasing heat transfer efficiency and enabling smaller, denser, and more powerful server architectures.

The plumbing behind these systems is becoming ever more sophisticated, from distributed supply/return loops to safe, redundant waste heat rejection pathways.

Modular, scalable systems for rapid growth.

AI data centre projects routinely require expansion in months, not years. Mechanical engineers are adopting modular HVACR components (dry coolers, heat exchangers, quick-close valves) that can scale up or down with changing IT loads. This flexibility allows facilities to respond to business and technology shifts with unprecedented speed.

Cold climates and natural cooling: the Telus Quebec innovation.

Facilities are increasingly sited to leverage geographic advantages. Telus’s sovereign AI factory in Rimouski, Quebec, epitomizes this approach.

The data centre operates on 99% renewable hydroelectric power and takes advantage of the region’s naturally cold climate to provide passive, free cooling for much of the year. By integrating natural outside air into the HVAC system, overall energy efficiency is boosted to nearly three times the industry standard. Additionally, optimized plumbing design and water management systems reduce fresh water use by 75%, aligning operations with growing environmental priorities. These innovations not only drive down operating costs but also make a direct impact on environmental sustainability.

Underwater data centres: harnessing the ocean for radical cooling.

Some of the world’s most forward-thinking data centre projects are going even further, installing server pods underwater

Servers are enclosed in sealed modules immersed in dielectric fluids, transferring heat directly to the surrounding cold seawater, eliminating the need for fans or air conditioning altogether. This underwater cooling approach can reduce energy consumption and emissions by up to 40% compared to conventional air-cooled facilities. Beyond efficiency, these submerged data centres offer exceptional physical security due to their inaccessibility, minimize land use, and operate with minimal on-site human intervention.

China and Subsea Cloud are notable pioneers in this field, showing that radical solutions are not only viable but are actively being implemented worldwide.

Plumbing systems: backbone of innovation.

The leap in cooling technologies requires a corresponding leap in plumbing engineering. Advanced coolant delivery networks support both cold plate and immersion systems, with failsafes that guarantee mission-critical uptime. Waste heat rejection pathways, whether to ambient air, water bodies, or specialized sinks, must be robust, reliable, and environmentally responsible. Plumbing redundancy and durability are essential as facilities scale and adapt rapidly to meet evolving operational demands.

Rapid engineering cycles: idea, test, build, repeat.

The pressure to keep up with computing advances has upended traditional timelines. Facility design and mechanical system prototyping now advance at near-startup speed, with iterative testing, simulation, and field deployment compressed into just months. Engineers collaborate across disciplines, including IT, mechanical, and sustainability, to develop solutions that can be quickly scaled and implemented. This culture of experimentation and rapid development is now a defining feature of the industry.

Conclusion: Racing toward the future.

The transformation of HVACR and plumbing services for AI and high-performance data centres is a testament to the industry’s ingenuity. With every new facility, the bar for efficiency, sustainability, and adaptability is raised, powered by bold engineering, rapid prototyping, and an unwavering drive to keep up with the unstoppable march of technology. Mechanical professionals stand at the forefront, not just reacting to demands but shaping the very foundation of tomorrow’s digital infrastructure.

The future of high performance data centres – True Mechanical.

Across Vancouver and Western Canada, True Mechanical continues to lead mechanical innovation, collaborating with clients and engineers to integrate these next-generation systems from the earliest design phase.

If you have a project you’d like to discuss, contact our team and lets make something happen.

Frequently Asked Questions.

What are Liquid Cooling and Immersion Technologies?

Liquid cooling involves circulating cooled fluids (often water or dielectric liquids) directly to server components or submerging entire hardware racks in non-conductive liquids. This method offers targeted and highly efficient heat management, ideal for AI and quantum computing with extreme rack densities.

Best Practices:

-Use closed-loop cooling to recirculate coolant and minimize water consumption.

-Employ direct-to-chip and immersion systems in highest-density settings.

-Regularly inspect and maintain plumbing integrity to prevent leaks and maximize uptime.

Leading Technologies:

Direct-to-chip systems (CoolIT, Vertiv), dielectric immersion tanks (Submer, Asperitas), and modular coolant distribution units (CDUs) are rapidly driving adoption.

Economic & Commercial Impact:

Enables higher rack densities without expanding facility footprint, improves uptime, and reduces operating costs through energy savings and hardware longevity. Facilities can also reuse waste heat for district heating, unlocking new revenue streams.

Environmental Benefits:

Lower electricity consumption (reduced PUE), decreased water use (via closed-loop), and opportunity to repurpose heat for sustainable applications.

Data Centre Sustainability: Water and Energy use.

Sustainable cooling focuses on minimizing water and energy drawn by HVACR systems, measured by Power Usage Effectiveness (PUE) and Water Usage Effectiveness (WUE).

Best Practices:

-Prioritize energy-efficient chillers, evaporative cooling, and renewable energy sources.

-Implement closed-loop liquid cooling or air economization for reduced water consumption.

-Monitor and optimize systems with real-time analytics to maintain low PUE/WUE.

Leading Technologies:

High-efficiency chillers (Johnson Controls, Trane), low-water use cooling towers, and DCIM monitoring platforms are industry benchmarks.

Economic & Commercial Impact:

Achieving low PUE/WUE ratings boosts marketability, secures regulatory compliance, and lowers utility costs. Customers increasingly demand green certifications and responsible water stewardship.

Environmental Benefits:

Reduces strain on local water supplies and carbon emissions, supporting corporate sustainability goals and community health.

Heat Reuse and District Heating Integration.

Instead of discarding waste heat, data centres capture and transfer it to adjacent buildings and district heating networks, making the data centre a source of clean thermal energy.

Best Practices:

-Implement heat exchangers and insulated plumbing for safe, efficient heat rejection.

-Design infrastructure for modular heat capture and easy integration with municipal networks.

-Ensure regulatory compliance and environmental monitoring as part of planning.

Leading Technologies:

Plate heat exchangers (SWEP, Alfa Laval), modular district heating connections, heat pumps, and automated monitoring platforms lead this space.

Economic & Commercial Impact:

Provides new revenue from heat sales, reduces heating costs for nearby facilities, and enhances a data centre’s service portfolio.

Environmental Benefits:

Cuts total energy waste, replaces fossil-fuel-based heating, and supports urban decarbonization efforts.

AI and Smart Control in HVACR.

AI-driven platforms intelligently manage and optimize HVACR operations, predicting heat loads, adapting controls, and detecting faults in real-time to ensure energy and cooling efficiency.

Best Practices:

-Deploy machine learning models for predictive maintenance and thermal optimization.

-Integrate IoT sensors for granular environmental monitoring and fast response.

-Use adaptive controls to match cooling delivery to live server demands.

Leading Technologies:

Schneider Electric EcoStruxure, Siemens Desigo CC, Honeywell Forge, and various edge-based AI platforms are industry leaders.

Economic & Commercial Impact:

Reduces energy costs, decreases downtime, and maximizes lifespan of cooling assets. AI-driven systems are increasingly differentiating facilities in a crowded market.

Environmental Benefits:

Dynamically reduces waste, avoids overuse of cooling resources, and lowers emissions via precision management.

Cooling Startups and Technology Provider Comparisons.

With demand soaring, new startups and established vendors compete to deliver cutting-edge cooling solutions. Industry searches target company profiles, technology demos, and comparative performance.

Best Practices:

-Evaluate providers on scalability, sustainability credentials, and total cost of ownership.

-Trial new products in pilot deployments before large-scale rollout.

-Scrutinize support services and vendor transparency for reliability.

Leading Technologies:

CoolIT, Submer, Asperitas, LiquidStack, and Vertiv stand out for novel products in immersion, direct-to-chip, and modular cooling.

Economic & Commercial Impact:

Early adoption enables competitive advantage from efficiency gains, marketing leverage, and improved operational reliability.

Environmental Benefits:

Most leaders champion greener solutions and energy reduction, making environmental impact a key criterion for market success.