The role of AI in mechanical design.

According to a Boston Consulting Group report (BCG) ‘The construction industry has long lagged behind in productivity, but data and AI are finally turning that tide. Those who adapt early will set the pace for the next generation of building’. As someone working closely with mechanical systems in the VDC (Virtual Design and Construction) process, I couldn’t agree more. I’ve witnessed first-hand how the adoption of AI tools is no longer just an advantage – it’s becoming a necessity. In this article, I’ll share how AI can support mechanical designers during the VDC process, reduce manual repetition, and ultimately help build smarter, faster, and more accurately.

Mechanical design using AI.

AI isn’t just transforming how we model – it’s changing how we create tools for modelling. –You no longer need to be a seasoned developer to build custom Revit extensions. With AI, even those with beginner-level coding skills can start solving problems.

Build Your Revit Tools with AI

A great example came up during one of my recent VDC tasks. We were working with an extremely tight mechanical room filled with prefabricated spools. To make it easier to manage on-site, we divided the space into zones and assigned a skid to each one. But when it came time to rename the assemblies using zone abbreviations – without breaking the numbering sequence – Revit didn’t give us a native solution.

So, I turned to ChatGPT for help. Despite my very limited experience with Python, I ended up building a simple but powerful Revit extension that handled the renaming automatically. This experience showed me that AI along with pyRevit isn’t just for big, complex automation. It can support everyday VDC tasks, helping designers like me build custom tools that make our workflow smoother and more efficient.

If you’re curious, I shared the full story and demo in this LinkedIn post – and I’d love to hear how others are using AI to build custom Revit tools in their workflows.

Future proof your mechanical design with AI.

A well-built Revit family is more than just geometry – it’s a tool. And the more flexible and parametric your families are, the more value they bring across multiple projects. Reusable, adjustable, and intelligent families reduce rework and increase consistency across your VDC workflows.

Build Your Revit Family Like a Pro

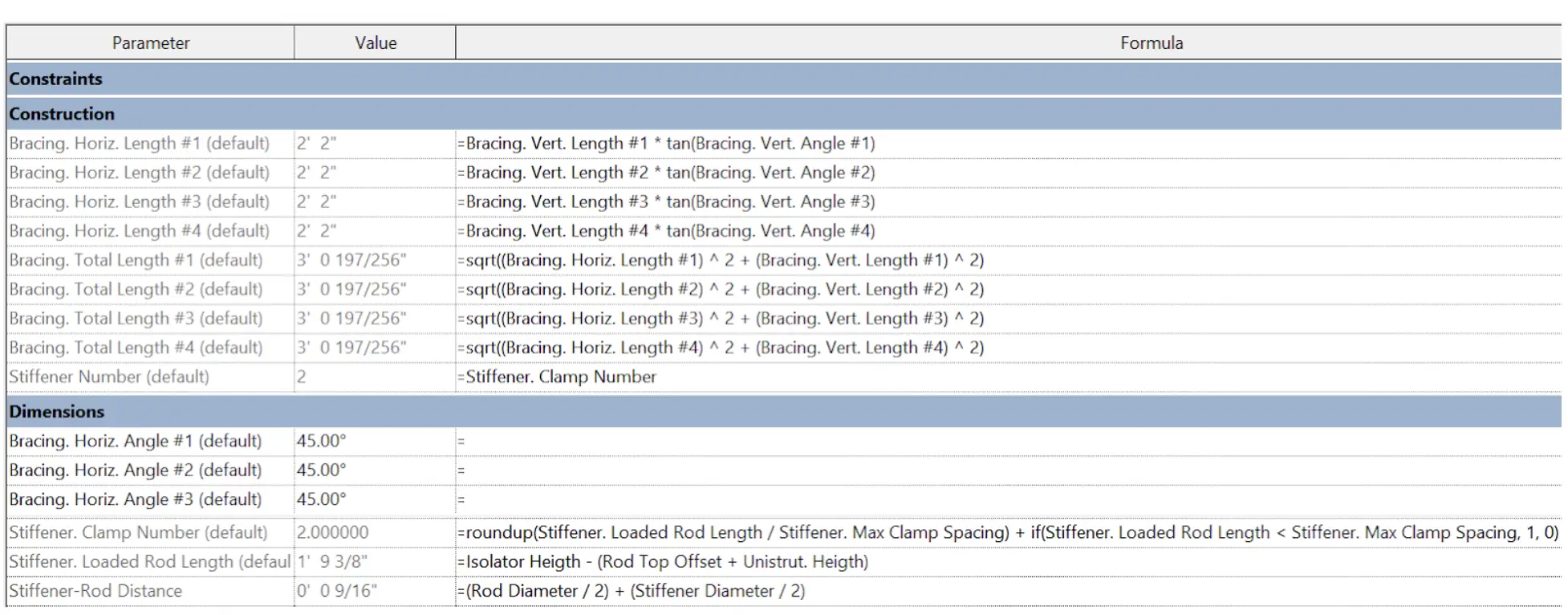

One of the best examples of the role of AI in mechanical design is an adaptive support family I developed a year ago, and I continue using it in projects today. One of the core goals was to ensure every detail – from angles and rod lengths to stiffener logic – could be controlled through parameters. For example, the family automatically adds stiffeners when rod lengths exceed a defined threshold, ensuring both structural integrity and compliance with fabrication standards.

But here’s the part I want to emphasize: I didn’t do all the formula logic alone. I relied on ChatGPT to help structure the complex formulas needed in the parameters. AI turned what could have been a frustrating trial-and-error process into a focused and efficient design experience. The result? A family that not only works well visually, but also feeds seamlessly into material takeoff schedules – every component is countable, making BOM (Bill of Materials) proposals smoother and more accurate.

I explored this project in more detail in this LinkedIn post. If you’re building families for MEP fabrication or equipment support, this might give you a few new ideas.

“By understanding the role of AI in mechanical design we’ve redefined how our VDC teams work—delivering faster, smarter solutions that boost performance, cut delays, and give our clients a true competitive edge.” — Brad Hedblom, President – True Mechanical

Smarter mechanical design using AI.

Beyond modelling and automation, AI can also be a valuable assistant during the coordination and decision-making phases of VDC. In large, multidisciplinary projects, understanding the impact of design changes, resolving conflicts, or even preparing summaries for team meetings can be overwhelming. This is where AI’s ability to process and simplify complex information shines.

Make Smarter Decisions with AI-Assisted Coordination

In my experience, using ChatGPT to rewrite RFI drafts or generate visual summaries for internal coordination has saved time – and made communication with other teams clearer. Instead of re-explaining a problem several times, I can present it once, with supporting context and even a resolution path already drafted. And it’s not just about writing better – it’s about thinking better. AI helps you frame the problem clearly, catch missing context, and prepare smarter proposals that keep coordination moving forward.

AI tools can help you:

- Summarize the clash detection reports to highlight critical issues first

- Draft clear, well-structured RFIs based on model context

- Track repetitive coordination issues and suggest patterns or root causes

- Turn messy meeting notes or change logs into clean, actionable to-do lists

In complex VDC environments, speed and clarity are critical. AI can give you both – without replacing your judgment, but by sharpening it.

Benefits of AI in mechanical design.

AI isn’t replacing VDC designers – it’s empowering them. It’s giving us new ways to solve old problems, speed up repetitive workflows, and bring more clarity into complex coordination processes. You don’t need to be an expert to get started. You just need to be curious.

Whether it’s building smarter Revit tools, enhancing your families with intelligent parameters, or simplifying team communication, AI can help you do more – with less stress and better results. The tools are available. The benefits are real. Now it’s just a matter of who chooses to explore them first.

AI Mechanical Design FAQs

Here are the answers to some common questions we get asked regarding AI and its role in mechanical design.

How is AI being used for mechanical design?

AI helps automate repetitive modelling tasks, optimize system layouts, and assist with drafting complex formulas in Revit families. It also generates smarter coordination documentation like RFIs and clash reports.AI is transforming mechanical design by making the process faster, more efficient, and more innovative across several key areas:

1. Generative and Optimized Design

Generative design tools use AI algorithms to automatically explore thousands of design possibilities based on specified constraints and goals, such as weight, strength, cost, or sustainability. This enables engineers to discover novel, high-performance solutions that might not be intuitive to humans. AI can optimize complex design parameters in real time, quickly identifying the best configurations for performance, cost, or manufacturability.

2. Simulation and Analysis

AI-driven simulation models, such as deep learning algorithms, can predict the performance of mechanical systems much faster than traditional numerical methods, sometimes delivering results thousands or millions of times quicker. In fields like computational fluid dynamics (CFD) and finite element analysis (FEA), AI accelerates simulations, automates mesh generation, and helps identify failure points or design flaws early in the process.

3. Quality Control and Inspection

Vision AI and machine learning are used for real-time defect detection and automated inspection, ensuring consistent quality and reducing the reliance on manual checks. AI can analyze sensor data and images to spot even the smallest defects, improving product reliability and customer satisfaction.

4. Predictive Maintenance and Real-Time Monitoring

AI models analyze real-time data from sensors embedded in mechanical systems to predict failures, schedule maintenance, and reduce downtime. This predictive capability helps companies save costs and improve the longevity of their machinery.

5. Material Science and Selection

Machine learning algorithms process large databases of material properties, helping engineers discover new materials or select optimal ones for specific applications, speeding up innovation in material science.

6. Digital Twins and IoT Integration

AI-powered digital twins create virtual replicas of physical systems, allowing engineers to simulate and optimize performance using real-world data without physical trials. Integration with IoT enables dynamic design adjustments based on operational feedback, leading to more resilient and efficient products.

7. Automation of Routine Tasks

AI automates repetitive tasks in CAD modeling, documentation, and data analysis, freeing engineers to focus on creative and high-value work.

8. Enhanced Collaboration and Accessibility

AI-driven platforms facilitate collaboration between human designers and AI, providing real-time feedback and making advanced design tools more accessible as implementation costs decrease.

Will AI replace mechanical designers?

No. AI is a powerful assistant, not a replacement. It handles tedious or repetitive tasks, allowing designers to focus on creativity, problem-solving, and engineering judgment. AI will not replace mechanical designers, but it is fundamentally transforming their roles and the skills required in the field.

Why AI Won’t Fully Replace Mechanical Designers

AI as a Tool, Not a Substitute: AI excels at automating repetitive tasks, optimizing designs, running simulations, and generating multiple design options. However, it lacks the human intuition, creativity, and engineering judgment needed to assess real-world feasibility, balance trade-offs, and innovate beyond data-driven patterns.

Human Oversight Remains Critical: Mechanical design involves understanding physical constraints, regulatory standards, manufacturability, and the practicalities of assembly and testing. AI can suggest or optimize solutions, but human designers must validate, interpret, and refine these outputs to ensure safety, reliability, and practicality.

Collaboration is the Future: The most likely scenario is a collaborative one, where AI augments the work of mechanical designers. Engineers will increasingly use AI as a co-designer or assistant, enabling them to focus on higher-level problem-solving, creative innovation, and decision-making.

Evolving Roles and New Opportunities: Rather than eliminating jobs, AI is creating new roles, such as AI-assisted design specialists and smart manufacturing engineers. The demand for mechanical engineers with advanced digital and AI skills is rising, not falling.

What is the best AI for mechanical design?

There’s no single “best” AI tool yet. General AI like ChatGPT helps with scripting and documentation, while specialized tools (such as pyRevit or Dynamo) are emerging to automate specific modelling tasks.

How is AI used in construction coordination?

AI can summarize clash reports, identify trends in coordination issues, suggest resolution paths, and streamline communication between disciplines during project meetings. Here’s a breakdown of key applications:

1. Real-Time Collaboration & Communication

AI-powered platforms (e.g., BIM-integrated tools) centralize project data, enabling teams to share updates, track progress, and resolve conflicts in real time. Natural language interfaces allow workers to query contracts, specifications, or schedules using voice or text, reducing delays in decision-making.

2. Automated Scheduling & Resource Allocation

Predictive AI analyzes historical and real-time data to forecast delays, optimize labor shifts, and allocate materials efficiently. Generative AI compares construction methods (e.g., prefab vs. traditional) to recommend cost-effective timelines and workflows.

3. Risk Mitigation & Issue Resolution

AI-driven analytics (e.g., Autodesk Construction IQ) flag risks in RFIs, submittals, or safety hazards, prompting proactive fixes. Computer vision monitors sites via drones or cameras to detect safety violations, misplaced materials, or quality defects.

4. Design Coordination & Clash Detection.

Generative design tools use AI to optimize architectural, structural, and MEP layouts, reducing conflicts during planning. Automated clash detection in BIM models identifies design inconsistencies early, minimizing rework.

5. Supply Chain & Logistics Optimization

AI forecasts material demand and tracks shipments in real time, preventing shortages or overstocking. Autonomous Mobile Robots (AMRs) and drones manage inventory, reducing manual errors and delays.

6. Safety & Compliance Monitoring

AI wearables track worker movements to prevent accidents, while sensors monitor equipment health for predictive maintenance. Automated documentation ensures compliance with regulations by logging safety protocols and inspections.

7. Progress Tracking & Reporting

AI dashboards aggregate data from IoT sensors, drones, and BIM to visualize progress and generate automated reports. Predictive insights compare actual vs. planned metrics, enabling mid-project adjustments.

Key Tools & Technologies

Generative AI: Autodesk, Civils.ai.

Risk Analytics: Autodesk Construction IQ.

Autonomous Equipment: AMRs, LiDAR drones.

BIM Integration: AI-enhanced platforms like Revit.

Let’s Build the Future Together.

Mechanical contracting is more than pipes and ducts; it’s about creating environments where people can live, work, and thrive comfortably. As the industry evolves, True Mechanical remains committed to innovation, quality, and sustainability.